I drained and re-filled the differential housing on Sunday morning. It wasn't as empty as I feared but when I stuck my pinky in the filler hole it came out with very black oil on it - so I drained it.

After re-filling the diff, I ran the car on axle stands and over the first 30 seconds or so everything quietened down noticably. I hope there is not any long-term damage.

On Sunday afternoon I put a new configuration in the controller - this one has regen and battery-alert-regen-cutout only if you are de-accelerating when the alert goes off. Whoops - no regen. again. I removed one function block - one that stops regen under 1.4km/h, and regen. was back. That was fine, the block was only to conserve power when stopped at lights etc and I can just turn it to neutral.

So William and I grabbed our phones, the Lenze manual and a User Input Keypad/display (stlll not mounted in the cabin but I can plug it into the controller if I have to), and set out. The "trip" was around the very large block formed by four major roads - about an 8km square. We would never be more than couple of minutes from home (centre of big block) should be get a low voltage alert. The Headways (batteries) give me about 2 minutes of power once I get the alert before I damage any cells.

At the start of the trip we had 1km on the trip meter and 54km range. I hadn't charged it since the 1km trip last weekend. After the first couple of kilometers we felt a bit more confident - regen braking was great and I didn't need the brake pedal except when stopped on a hill. At about the 3km mark the range had dropped to 49km - not good. We kept going and at the end of the hill down one side of the square we were back up to 54km - great. I hadn't touched the brake pedal yet - all our stopping was happening on regen braking. Generally I was getting about 15 Amps into the pack at about 50km/h. Regen worked all the way down to stop with one minor problem - the Vogue always wanted to go BACKWARDS about a meter once we had stopped. Gently holding the acccelerator down a bit stopped this tendency and I turned the enable off (neutral) each time we had to stop for more than a few seconds. I need that function block after all!

On the first leg we stopped at a service station and put 32psi into all tyres. The service station queue to the bowsers was quite long but we ignored it.

We went around about 2 1/2 times then cut through the middle sides streets to visit a relative who lives nearby, then home.

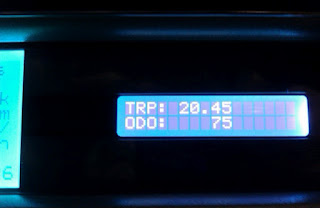

Here are the dash board pictures once we were back in the garage.

The pictures tell it all (almost). I am amazed at the economy given one leg of the square travel speed is 70 to 80km/h. Our range on arriving home was similar after 20km to the value when we left. I attribute this to better tyre pressure - they have been 25psi for previous drives, surface rust on front brake rotors and rear drums finally getting a chance to be rubbed off, and a differential housing with the right quantity of oil in it. It could also be that this was the first drive under normal circumstances and at reasonable speeds. (Of course I could have a massive conceptual bug in the range estimation as well!)

(Later addition. I realised that the real reason for the improved range after this drive was that I "*fanged" it around the block the previous weekend for that one kilometer, with no regen, so the range estimate started out rather pessimistic at the start of our 20km drive.)

*Vogue version of fanged at the moment is still rather tame.

Problems.

- The car is noisy. Suspension squeaks and maybe the front wheel bearings need a clean and re-packing.

- The speedo and perhaps trip/ODO are inaccurate. The display reads 67km/h when our GPS says 60km/h - so about 10%. Expensive signal generators and frequency meters and still I mucked up. The tyres on the car vs the ones the speedo cluster was calibrated for should have the error the other way. The tyres currently on the car are larger.

- I still have a small "thump" on the transition from regen to accelerate.

Minor problems aside, I was extremely happy with the drive and more than happy with wh/km - even with the 10% error. (About 132 wh/km battery to wheel.)