Electric Vogue

This blog documents the restoration, and conversion, of a 1965 Humber (Singer) Vogue to a fully electric vehicle. The Vogue will be powered by an 11kW(modified), 3 phase industrial AC motor, controlled by an industry standard Variable Speed Drive (VSD) or Inverter. To be able to produce the 400 volts phase to phase the VSD will need about 600 VDC of batteries. A big thanks to the contributors on the AEVA forum: http://forums.aeva.asn.au/forums/

Wednesday, October 28, 2020

Still Going

A couple of folk have asked me about the Vogue since there hasn't been any blog entries for a while. Yes it's still going - and still waiting for the front end components to be fitted. The batteries have suffered a little from calendar life degradation but all 384 cells appear to be tracking each other pretty well. Range is down to around 55km. I'm always looking out for new cells to fit in the same place as the headways and if I can get the ones I like it would give me about 240km range. The pack weight would go from 140kg to just under 200kg - not bad. Hard to justify though as the range still gets me where I want to go and back.

Wednesday, March 14, 2018

New Charge Timer

My cheap Chinese 16A charge timer died again - this time not fixable. The relay contacts appear to be fried.

I built the hardware for this one a couple of years ago using the timer and CB from the decommissioned air conditioning system at work (had to raid the dumpster).

So all wired now and working nicely. I have yet to mount it permanently.

This time I can replace the contactor etc. If they fail.

Wednesday, September 13, 2017

No wonder they Fail

This socket has been under cover for weeks but it still gets a bit of moisture in it. My reckoning is the heat cycling sucks in moist air as it cools down every night.

Labels:

chargers

Friday, April 21, 2017

Vogue passes 30,800 km

I have been a bit lax updating the blog lately but the Vogue passed 30,000 km a month or so ago so I got a picture yesterday.

Labels:

Driving

Monday, February 13, 2017

Transmission for consideration in the Vogue (not really)

I which I'd been able to get one of these when I was designing the Vogue drive train.

Labels:

Soapbox

Tuesday, January 10, 2017

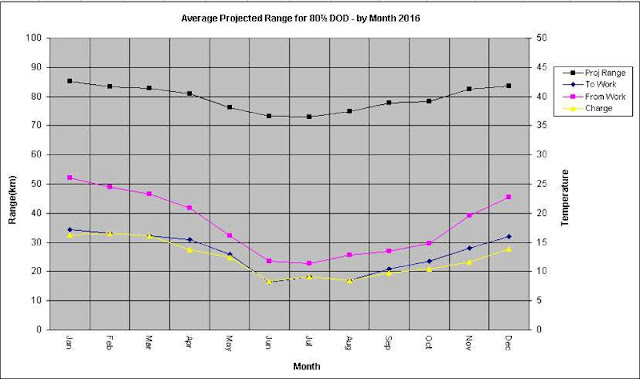

Temperature and Projected Range for 2016

Here is the full year's graph of the eVogue's projected range vs temperature for 2016.

Summer is December to February here in Australia.

I have logged the temperatures for the drive "To Work" at about 8:30AM, the "From Work" at around 5:30PM and the "Charge" temperature at around 4AM (I start charge at 3AM and it usually stops at 5 or 5:30AM).

The magic number for 80km total range appears to be 15 degrees C.

Summer is December to February here in Australia.

I have logged the temperatures for the drive "To Work" at about 8:30AM, the "From Work" at around 5:30PM and the "Charge" temperature at around 4AM (I start charge at 3AM and it usually stops at 5 or 5:30AM).

The magic number for 80km total range appears to be 15 degrees C.

Labels:

Driving,

Power economy

Wednesday, November 16, 2016

That NOISY EV

Reuters - 14th November.

The U.S. government on Monday finalized long-delayed rules that will require "quiet cars" like electric vehicles and hybrids to emit alert sounds when they are moving at speeds of up to 18.6 miles per hour (30 km per hour) to help prevent injuries among pedestrians, cyclists and the blind.

The U.S. government on Monday finalized long-delayed rules that will require "quiet cars" like electric vehicles and hybrids to emit alert sounds when they are moving at speeds of up to 18.6 miles per hour (30 km per hour) to help prevent injuries among pedestrians, cyclists and the blind.

The rules, which were required by Congress, will require automakers like Tesla Motors Inc (TSLA.O), Nissan Motor Co (7201.T) and Toyota Motor Corp (7203.T) to add the sounds to all vehicles by September 2019. The U.S. Transportation Department said it expects the rules would prevent 2,400 injuries a year by 2020 and require the addition of alert sounds to about 530,000 2020 model vehicles.

It looks like I'll be installing that EV SoundRacer in the Vogue before too long.

Labels:

Driving

Tuesday, November 15, 2016

Range vs Temperature by Day

Since I have noted temperature to and from work and charge temperature for the past three and a half months I can now verify that 15 degrees C is the magic number. Above 15 degrees and I go above (or close to) 80km projected range.

September is an excellent example (colder than last year).

October is a bit more scatty as I did a couple of "don't care about range" trips but the trend is still evident.

November has warmed up and just about every day's drive home is above 15 degrees so projected range is following.

Month by month so far for 2016.

You can see the unusually cold October.

Compared to last year.

September is an excellent example (colder than last year).

October is a bit more scatty as I did a couple of "don't care about range" trips but the trend is still evident.

November has warmed up and just about every day's drive home is above 15 degrees so projected range is following.

Month by month so far for 2016.

You can see the unusually cold October.

Compared to last year.

Labels:

Driving,

Power economy

Monday, October 3, 2016

Renewable Energy attack after Storm in S.A.

Sorry I can't embed this video.

https://www.facebook.com/Senator.Sarah.Hanson.Young/videos/1204537329569759/

https://www.facebook.com/Senator.Sarah.Hanson.Young/videos/1204537329569759/

Labels:

Renewable energy,

Soapbox

Wednesday, August 10, 2016

Range and Temperature

I have collected temperature data this year in an attempt to understand a little more about what effects range the most from summer to winter.

I have logged my drive to work temperature, drive home (From Work) temperature and charge temperature.

It looks like the highest correlation with projected range is the drive home. That may simply reflect the daytime temperature of course.

Temperature is in degrees C.

(Edit: 27 Sep 2016 Updated - again)

I have logged my drive to work temperature, drive home (From Work) temperature and charge temperature.

It looks like the highest correlation with projected range is the drive home. That may simply reflect the daytime temperature of course.

Temperature is in degrees C.

(Edit: 27 Sep 2016 Updated - again)

Labels:

Driving,

Power economy

Friday, June 24, 2016

More Robot Dogs

I love this stuff - it scares me a little but it's fascinating.

(I reckon they classify as EVs.)

Make sure you watch the last few seconds....

(I reckon they classify as EVs.)

Make sure you watch the last few seconds....

Labels:

Renewable energy

Thursday, June 16, 2016

Dark Red Nissan Leaf

I followed a dark red Leaf through the back streets of Scoresby for a couple of kilometers today.

Anyone?

Getting cold in Melbourne. In winter range territory now.

Anyone?

Getting cold in Melbourne. In winter range territory now.

Labels:

Driving

Friday, June 3, 2016

Battery Charger Repair

As I've posted a while back, I have had some charger failures during the time I have been driving the Vogue.

To racap. TheVogue has 12 sub-packs each with 32 cells in it arranged as 2P16S (2 cells in Parallel and 16 cell pairs in series), making about a 53 VDC sub-pack. Each sub-pack has its own 3A charger.

The chargers cost me around AU$36 each - they were cheap. That said they are pretty well built and I am not absolutely sure that it's not partially my fault that they fail (my modification described here may cause instability in the current limit due to the proximity to the toroid). (Update 15th Nov 2016 - I'ts not my fault. I checked a charger that was running at 4.2 Amps and moved the daughter board around - it made no difference. They just drift up!)

It's also worth noting that I didn't have any failures from April 2014 to March 2016 - two years.

Generally the main power transistors fail (FJP13009) but in two of the chargers the switch mode power transformer has failed with shorted turns. I've been "sitting" on the first failure of this nature for over two years - mucking about with rewinding it (it worked but I couldn't fit enough turns on the core so I only got 3A up to 48V - I needed 59V).

Disassemble...

So when the second charger failed in April this year (2016) with the same transformer fault I got my act into gear and actually bought the correct enamel wire to rewind the first failed transformer.

So last night the repaired charger was included in my nightly charge and worked fine.

I really can't imagine why anyone would wind these transformers as a hobby (folk who play around with 12V to 240VAC inverters etc) - it's difficult.

Anyway, I have found a source of cores (the ferrite stuff) and bobbins (the plastic bit you wind the wire around with pins to terminate them) on eBay so I can make up some spares.

WHY DO THEY FAIL?

Over three years driving and charging and fixing this stuff and I finally have some understanding of (and a method of predicting) the failures.

The most recent failed charger was on pack #7. I had noted that pack #7 had been charging faster than the remaining 11 packs in the car and calculated it at over 4A charge rate. The chargers are really pretty maxed out at 3A - heat wise. I knew that I should pull it out and back it off - but I deferred - too cold outside recently.

So it wasn't too much of a surprise when the charger for pack #7 failed - now I know more.

It's also notable that the Vogue draw slightly but measurably more power during charging (energy monitor logging overnight) when a charger has become unstable (more on that another time) - so I can see it within a couple of days and take action.

Labels:

chargers

Wednesday, May 11, 2016

400ppm CO2 Threshhold About to be Crossed

Cape Grim in Tasmania, Australia is about to be the first place in the world where the CO2 content in the Earth's atmosphere is measured at 400ppm.

"The following chart, compiled by CSIRO researchers using atmosphere and ice core readings, show how CO2 levels have risen over the past 2000 years."

"Cape Grim's readings are significant because they capture the most accurate reading of the atmospheric conditions in the southern hemisphere and have records going back 40 years."

The 400ppm figure has been temporarily exceeded in the past but this time there will be no going back.

More here: Age Article

Oh, and the Vogue just passed 23300 Electric km on the Odometer.

"The following chart, compiled by CSIRO researchers using atmosphere and ice core readings, show how CO2 levels have risen over the past 2000 years."

"Cape Grim's readings are significant because they capture the most accurate reading of the atmospheric conditions in the southern hemisphere and have records going back 40 years."

The 400ppm figure has been temporarily exceeded in the past but this time there will be no going back.

More here: Age Article

Oh, and the Vogue just passed 23300 Electric km on the Odometer.

Labels:

Renewable energy,

Soapbox

Thursday, March 17, 2016

The Wedding Pictures are in!

The professional pictures are now available. Emma just made this short montage (just over 3 minutes) available for Tammy and Matt. The Vogue features a lot.

Link to Vimeo version.

Tammy and Matthew from emmawisephotography on Vimeo.

Link to Vimeo version.

Tammy and Matthew from emmawisephotography on Vimeo.

Monday, February 8, 2016

More wedding pics

I had a special spot in the shade reserved for the Vogue during the ceremony.

It was a 10AM ceremony and 12 Midday reception. It worked out well for the non-air-conditioned Vogue's occupants. A pleasant 40 minute drive to the Chapel with temperature at about 21 degrees C. A tad hot at 12:10 PM when we moved again but it was only a four minute drive to the reception.

About to leave home for the drive down to Brighton. The Man of Honour (son) travelled with Laurel (wife) in her car so it was just Tam and me.

The Bride and Groom were picked up from the reception in a Tesla.

It was a 10AM ceremony and 12 Midday reception. It worked out well for the non-air-conditioned Vogue's occupants. A pleasant 40 minute drive to the Chapel with temperature at about 21 degrees C. A tad hot at 12:10 PM when we moved again but it was only a four minute drive to the reception.

About to leave home for the drive down to Brighton. The Man of Honour (son) travelled with Laurel (wife) in her car so it was just Tam and me.

The Bride and Groom were picked up from the reception in a Tesla.

Sunday, February 7, 2016

Daughter gets Married - the Wedding car?

My daughter Tammy was married yesterday and it was my honour to provide the wedding car at her request. She and her husband (sounds weird) began serious dating in 2009, just around the time I started the Vogue restoration and electrification.

A Tesla took them from the reception to a city hotel so she travelled entirely electric for the big day.

More pictures to come...

A Tesla took them from the reception to a city hotel so she travelled entirely electric for the big day.

More pictures to come...

Tuesday, January 12, 2016

Summer range, Getting 90km predicted

I'm getting 90km predicted range on my normal drive to work now that it's warmer weather again. My previous post showing just past 20,000km was a bad day with a few little trips. (Even EVs don't like those sub 5km local trips.)

I don't get much time to take my logging picture in the morning a we are usually in a rush to get my daughter to the station, but I did get a second shot when I saw the bad light reflection.

I don't get much time to take my logging picture in the morning a we are usually in a rush to get my daughter to the station, but I did get a second shot when I saw the bad light reflection.

Labels:

Driving,

Power economy

Monday, December 14, 2015

Vogue passes 20,000km

I meant to stop and snap a picture when the Vogue hit 20,000 electric kilometers but it slipped by without me noticing. I only realised this morning when I took my standard picture so that I could update the daily charging spreadsheet.

(Sorry for the hand reflection.)

(Sorry for the hand reflection.)

Labels:

Driving

Thursday, October 8, 2015

Range Improving for Summer

It's been a long winter - not too wet but colder for longer.

The Vogue range is returning to 80+km. Withfour nine 17 charges recorded for October it's looking good. It's unusual for August to be similar temperatures to June and July in Melbourne.

The Vogue is up to 18937 electric kilometers.

(Image and numbers updated 30th Oct 2015)

The Vogue range is returning to 80+km. With

The Vogue is up to 18937 electric kilometers.

(Image and numbers updated 30th Oct 2015)

Labels:

Driving,

Power economy

Monday, September 21, 2015

The Story of Stuff

31st-Aug-2016. Rusdy left a comment for another great site that I'll link to here.

http://ourrenewablefuture.org/

Labels:

Renewable energy,

Soapbox

Wednesday, July 29, 2015

The Vogue awaits an Engine in 2004

I stumbled across this picture taken on the 30th November 2004.

The Vogue sits patiently in the backyard waiting for an engine that doesn't need the head gasket changed every year. (I got the idea for electric in 2008.)

FCR Motion Technology in Melbourne, the local Lenze agent, have been absolutely no help whatsoever.

The Vogue sits patiently in the backyard waiting for an engine that doesn't need the head gasket changed every year. (I got the idea for electric in 2008.)

FCR Motion Technology in Melbourne, the local Lenze agent, have been absolutely no help whatsoever.

Labels:

restoration

Wednesday, June 24, 2015

Midwinter 2015 range

Ah winter is here again. Range down to around 73km for 80% depth of discharge.

This pic (taken once I got home again) was from a bad day with the drive to work starting out at 4 degrees C.

This pic (taken once I got home again) was from a bad day with the drive to work starting out at 4 degrees C.

Labels:

Power economy

Thursday, May 7, 2015

Strange Vogue Picture

I was on the way to work yesterday and a strange site caught my eye.

Can't see it? I'm not surprised - you probably had to be sitting on stationary traffic and bored to notice.

S

c

r

o

l

l

d

o

w

n

t

o

s

e

e

w

h

a

t

I

s

a

w

The shape of the Mazda rear hatch door turned the Vogue front view into a cartoon-like image.

The Mazda hatch must be more a triangle shape (in plan view) rather than a gentle curve.

Can't see it? I'm not surprised - you probably had to be sitting on stationary traffic and bored to notice.

S

c

r

o

l

l

d

o

w

n

t

o

s

e

e

w

h

a

t

I

s

a

w

The shape of the Mazda rear hatch door turned the Vogue front view into a cartoon-like image.

The Mazda hatch must be more a triangle shape (in plan view) rather than a gentle curve.

Labels:

Driving

Tuesday, March 31, 2015

Shrinking Weatherstrip

The strip that wipes the outside of the winding windows was sourced new for the Vogue when I re-fitted the winding windows. Referred to as door glass weatherstrip and a few other names,

I purchased mine in Australia and it appears similar to what is available at a few places here.

Unlike the original it has no reinforcing metal strip.

Trouble is - it shrinks!

Note also the waving lines where the clips are holding it inside the door.

The Vogue has "seen" two summers in active use now and the driver door weatherstrip is now about 22mm shorter than when I installed it.

The passenger side is a little better, but not much. The driver side is exposed to the Sun more than the passenger side and it shrunk first over the summer of 2013/2014 by about 15mm. (January/February is the peek of summer here.)

I have finally found something like the original with the metal strip buried in it and have ordered some from the UK.

I get the feeling that most Classic car restorations sit in garages most of the time and are not exposed to the weather much.

I purchased mine in Australia and it appears similar to what is available at a few places here.

Unlike the original it has no reinforcing metal strip.

Trouble is - it shrinks!

Note also the waving lines where the clips are holding it inside the door.

The Vogue has "seen" two summers in active use now and the driver door weatherstrip is now about 22mm shorter than when I installed it.

The passenger side is a little better, but not much. The driver side is exposed to the Sun more than the passenger side and it shrunk first over the summer of 2013/2014 by about 15mm. (January/February is the peek of summer here.)

I have finally found something like the original with the metal strip buried in it and have ordered some from the UK.

I get the feeling that most Classic car restorations sit in garages most of the time and are not exposed to the weather much.

Labels:

restoration,

windows

Monday, February 16, 2015

All's well for start of 2015

There's not much going on with the Vogue at the moment. It's my daily driver to and from work and is completely reliable. I do have to keep a check for charger failures but they seemed to have settled down. We are not getting the 40 degree days that are typical of this time of year so the Vogue is very pleasant to drive. The odometer reads just over 13000km.

Once minor change a few days ago is that I implemented a regenerative braking "boost". I have regen. set at the maximum I think is safe to run for wet roads etc. but every now and then, mainly when slowing down for a right turn lane, I'd like a bit more. (I also have it set so I don't exceed 2C to the batteries.) Now, when I press the reverse-interlock pushbutton on the dash, the regen. ramps up to 200% what I normally run. The ramp is over a 1 second period.

I don't seem to need to use it more than a couple of times a week but it's nice not to waste the energy with mechanical brakes.

Hi to the folks in France who seemed to have topped the Vogue blog page views last week.

Feel free to leave a comment...

Once minor change a few days ago is that I implemented a regenerative braking "boost". I have regen. set at the maximum I think is safe to run for wet roads etc. but every now and then, mainly when slowing down for a right turn lane, I'd like a bit more. (I also have it set so I don't exceed 2C to the batteries.) Now, when I press the reverse-interlock pushbutton on the dash, the regen. ramps up to 200% what I normally run. The ramp is over a 1 second period.

I don't seem to need to use it more than a couple of times a week but it's nice not to waste the energy with mechanical brakes.

Hi to the folks in France who seemed to have topped the Vogue blog page views last week.

Feel free to leave a comment...

Labels:

brake pedal,

Driving

Thursday, December 18, 2014

Monday, October 27, 2014

Letter to Engineer in 2012

I wrote this letter to the Engineer (that approved the Vogue) in January 2012 prior to his first visit.

It's actually one of the best summaries of the car - something lacking in the blog until now.

I began converting the Vogue to electric and restoring it about 2 1/2 years ago.

The Humber Vogue Mk3 (1965) is a medium sized sedan that was powered by a 1600cc overhead valve engine coupled to a Borg Warner 35, 3 speed automatic transmission. Made in Australia by the Rootes Group, the Vogue is very similar to the Hillman Minx of the era.

The Vogue has front 9" disc brakes with no booster, no power steering and no air conditioning. These things make the electric part a lot easier as there is no need to power a separate steering pump, vacuum pump or air conditioner pump. The Vogue is still registered and has been continuously for the past 47 years. I have owned it for about 17 years and driven it about 50,000km on the old engine.

The Vogue is now powered by a nominal 11kW induction motor (3 phase ACIM) that has been rewound to a lower voltage with high temperature windings, embedded thermister, independently powered cooling fan and shaft encoder. The motor can develop around 65kW peak and since the continuous rating of 11kW was at 1500 RPM, the manufacturers concur that it can comfortably maintain 22kW at 3000 RPM.

The motor is coupled directly to the tailshaft which has been custom modified to include a sliding spline.

The motor is driven by a Lenze 9329 DC to 3 phase Variable Speed Drive (controller) which in turn is powered by 384 Lithium Iron Phosphate cells arranged in 2 parallel 192 series to deliver around 600 VDC. The cells are packed into 12 battery subpacks of 32 cells each (2P16S). Each cell is 3.2 V, 10AH. Each sub-pack has it's own 3A charger.

Each sub-pack weighs 12kg. The accelerator is an Audi A6 pedal (new) and feeds a custom configuration in the controller that provided a very petrol engine-like "feel" with full Torque control. Being an AC system the Vogue has very powerful and configurable regenerative braking.

The entire battery pack is isolated from the car chassis and has a vacuum contactor at either end of the pack that is rated to break maximum voltage and current. In addition there are two contactors that isolate the center of the pack from a nominal "center" connection (required for the DC-DC 13.8 V convertors of which there are two). The control system will not allow the car to "start" unless it is in Neutral and the Charger is disconnected.

For the purpose of wiring layout and identification I generally refer to a +300V and a -300V side of the pack.

The packs can be broken into six isolated sections with hand-safe connectors and that is how I work in the vehicle.

The 12 chargers are sequenced on in four stages to avoid large mains inrush (in 2 second intervals). The car draws 2400 W from a 240 VAC supply. The mains supply inlet is protected with a combined 16A RCB/MCB.

The seven front battery sub-packs are split into four mounted on a 1.6mm stainless steel tray which is mounted on the firewall and to the front inner guards. The other three subpacks are on the motor frame. The motor frame mounts on the original engine and rear transmission rubber mounts.

Four of the rear five subpacks are mounted on an aluminium frame which is secured to the Vogue "upper" boot area immediately behind the steel rear firewall. The fifth rear subpack is securely mounted where the Vogue guard-mounted fuel tank used to reside.

All 12kg battery subpacks are secured with 300kg polypropylene camlock straps (Lion brand). The three front motor frame mounted subpacks have two straps each. All metal corners where straps are involved are rounded to a radius just short of the metal thickness, finished with 1200 grit wet-and-dry and, if aluminium or mild steel, painted.

While I did not weigh the car before starting, I did measure the ride heights of front and back, right and left sides, and have documented all weight removed and added to the vehicle. So far it is about 6kg lighter than original. A great deal of effort has been made to keep the weight distribution the same as original which meant "stuffing" as much as possible into the engine bay. For instance, my original design had six subpacks in the front and six in the boot but this was changed to seven in the front and five in the boot to move as much weight forward as possible (battery packs are light compared to cast-iron engine blocks).

There are very few places where I have had to drill new holes as the Vogue provided extensive mounting points. There has been no steel cut from the vehicle (other than drilled holes).

The Vogue has been professionally resprayed and is currently having a completely new interior fitted. The steering box has been professionaly overhauled and the car is entirely rust-free.

I have tried very hard to adhere to NCOP14 throughout the design and implementation of the conversion.

The "electric" or conversion part of this project has been 99.9% finished and drivable since July 2011 - the restoration has taken somewhat longer than I envisioned.

If I have left anything relevant out, a complete, up-to-date (and time consuming to read) build blog is available at:

http://electricvogue.blogspot.com/

Navigation is easiest and fastest if you use the "Labels" on the right of the page to pinpoint any specific areas of the build.

It's actually one of the best summaries of the car - something lacking in the blog until now.

I began converting the Vogue to electric and restoring it about 2 1/2 years ago.

The Humber Vogue Mk3 (1965) is a medium sized sedan that was powered by a 1600cc overhead valve engine coupled to a Borg Warner 35, 3 speed automatic transmission. Made in Australia by the Rootes Group, the Vogue is very similar to the Hillman Minx of the era.

The Vogue has front 9" disc brakes with no booster, no power steering and no air conditioning. These things make the electric part a lot easier as there is no need to power a separate steering pump, vacuum pump or air conditioner pump. The Vogue is still registered and has been continuously for the past 47 years. I have owned it for about 17 years and driven it about 50,000km on the old engine.

The Vogue is now powered by a nominal 11kW induction motor (3 phase ACIM) that has been rewound to a lower voltage with high temperature windings, embedded thermister, independently powered cooling fan and shaft encoder. The motor can develop around 65kW peak and since the continuous rating of 11kW was at 1500 RPM, the manufacturers concur that it can comfortably maintain 22kW at 3000 RPM.

The motor is coupled directly to the tailshaft which has been custom modified to include a sliding spline.

The motor is driven by a Lenze 9329 DC to 3 phase Variable Speed Drive (controller) which in turn is powered by 384 Lithium Iron Phosphate cells arranged in 2 parallel 192 series to deliver around 600 VDC. The cells are packed into 12 battery subpacks of 32 cells each (2P16S). Each cell is 3.2 V, 10AH. Each sub-pack has it's own 3A charger.

Each sub-pack weighs 12kg. The accelerator is an Audi A6 pedal (new) and feeds a custom configuration in the controller that provided a very petrol engine-like "feel" with full Torque control. Being an AC system the Vogue has very powerful and configurable regenerative braking.

The entire battery pack is isolated from the car chassis and has a vacuum contactor at either end of the pack that is rated to break maximum voltage and current. In addition there are two contactors that isolate the center of the pack from a nominal "center" connection (required for the DC-DC 13.8 V convertors of which there are two). The control system will not allow the car to "start" unless it is in Neutral and the Charger is disconnected.

For the purpose of wiring layout and identification I generally refer to a +300V and a -300V side of the pack.

The packs can be broken into six isolated sections with hand-safe connectors and that is how I work in the vehicle.

The 12 chargers are sequenced on in four stages to avoid large mains inrush (in 2 second intervals). The car draws 2400 W from a 240 VAC supply. The mains supply inlet is protected with a combined 16A RCB/MCB.

The seven front battery sub-packs are split into four mounted on a 1.6mm stainless steel tray which is mounted on the firewall and to the front inner guards. The other three subpacks are on the motor frame. The motor frame mounts on the original engine and rear transmission rubber mounts.

Four of the rear five subpacks are mounted on an aluminium frame which is secured to the Vogue "upper" boot area immediately behind the steel rear firewall. The fifth rear subpack is securely mounted where the Vogue guard-mounted fuel tank used to reside.

All 12kg battery subpacks are secured with 300kg polypropylene camlock straps (Lion brand). The three front motor frame mounted subpacks have two straps each. All metal corners where straps are involved are rounded to a radius just short of the metal thickness, finished with 1200 grit wet-and-dry and, if aluminium or mild steel, painted.

While I did not weigh the car before starting, I did measure the ride heights of front and back, right and left sides, and have documented all weight removed and added to the vehicle. So far it is about 6kg lighter than original. A great deal of effort has been made to keep the weight distribution the same as original which meant "stuffing" as much as possible into the engine bay. For instance, my original design had six subpacks in the front and six in the boot but this was changed to seven in the front and five in the boot to move as much weight forward as possible (battery packs are light compared to cast-iron engine blocks).

There are very few places where I have had to drill new holes as the Vogue provided extensive mounting points. There has been no steel cut from the vehicle (other than drilled holes).

The Vogue has been professionally resprayed and is currently having a completely new interior fitted. The steering box has been professionaly overhauled and the car is entirely rust-free.

I have tried very hard to adhere to NCOP14 throughout the design and implementation of the conversion.

The "electric" or conversion part of this project has been 99.9% finished and drivable since July 2011 - the restoration has taken somewhat longer than I envisioned.

If I have left anything relevant out, a complete, up-to-date (and time consuming to read) build blog is available at:

http://electricvogue.blogspot.com/

Navigation is easiest and fastest if you use the "Labels" on the right of the page to pinpoint any specific areas of the build.

Labels:

Engineer

Tuesday, September 16, 2014

Monthly Energy Usage to Spring 2014

I have deferred the front end work until I have time to clean up the wishbones etc.

Meanwhile, I am getting good range figures now that it's warmed up a little here in Melbourne.

Here is the up-to-date range history since I have been driving the Vogue on electricity.

Range is based on 80% Depth of Discharge (DOD) of the battery pack.

The anomaly in October 2013 was caused by two high speed trips raising the average of only eight recharges. June 2013 had only five recharges. I normally recharge about 20 times a month in winter (every weeknight) and about 15 times a month in Summer.

Edit: Updated 28th October 2014

Meanwhile, I am getting good range figures now that it's warmed up a little here in Melbourne.

Here is the up-to-date range history since I have been driving the Vogue on electricity.

Range is based on 80% Depth of Discharge (DOD) of the battery pack.

The anomaly in October 2013 was caused by two high speed trips raising the average of only eight recharges. June 2013 had only five recharges. I normally recharge about 20 times a month in winter (every weeknight) and about 15 times a month in Summer.

Edit: Updated 28th October 2014

Labels:

Driving,

Power economy

Tuesday, September 9, 2014

Vogue about to clock up 10,000km on Electric Power

My range is creeping back up now it's over 15 degrees C in the morning.

I quickly took this picture on the way to work. I had another 5km to go. The over-100km-projected-range didn't last long as I was about to go up a big hill - nice to see though.

(Range is Remaining Range - I should rename it sometime.)

So on the way home I'll go over the 10,000km.

I quickly took this picture on the way to work. I had another 5km to go. The over-100km-projected-range didn't last long as I was about to go up a big hill - nice to see though.

(Range is Remaining Range - I should rename it sometime.)

So on the way home I'll go over the 10,000km.

Labels:

Driving,

Power economy

Friday, September 5, 2014

CSIRO on Man made Climate Change

Perhaps some of our politicians might be a little more amenable to the idea of man-made climate change after CSIRO's latest report.

Sorry - I had to remove the picture as the CSIRO pages have changed.

Sorry - I had to remove the picture as the CSIRO pages have changed.

Labels:

Renewable energy,

Soapbox

Wednesday, August 6, 2014

Record for longest EV range at Highway speeds

No, it's not the Vogue...but this is pretty great.

http://www.wired.com/2014/08/eve-solar-powered-car-record/

http://www.wired.com/2014/08/eve-solar-powered-car-record/

Labels:

Renewable energy,

Video

Poodle playtime and Vogue passes 9000km

The Vogue passed 9000km on battery power at the start of this week.

Meanwhile the Rag stealers play...

Meanwhile the Rag stealers play...

Labels:

Driving,

rag stealer,

Video

Thursday, July 17, 2014

Power to the People

[Soapbox on]

A recent Four Corners (a credible Australian current affairs TV show) explored the utterly stupid Australian government's bias against renewable energy development.

I really do not understand what the LNP (current government) think they are doing in this country.We are losing so much to a lie that the economy is in trouble and matters more than anything else.Australia is turning into the "bad guy", pushing it's coal when it should be planning and "doing" for a very doable sustainable future.

The discussion over electricity companies being in trouble from not "predicting" the private rooftop generation and renewable energy effect just points to a blinkered dumb attitude that failed to do basic research into clear trends. This is not "wise in retrospect". Many people predicted this and took action - just not some Australian power companies.

Of course this is just my opinion.

Four Corners article.

A recent Four Corners (a credible Australian current affairs TV show) explored the utterly stupid Australian government's bias against renewable energy development.

I really do not understand what the LNP (current government) think they are doing in this country.We are losing so much to a lie that the economy is in trouble and matters more than anything else.Australia is turning into the "bad guy", pushing it's coal when it should be planning and "doing" for a very doable sustainable future.

The discussion over electricity companies being in trouble from not "predicting" the private rooftop generation and renewable energy effect just points to a blinkered dumb attitude that failed to do basic research into clear trends. This is not "wise in retrospect". Many people predicted this and took action - just not some Australian power companies.

Of course this is just my opinion.

Four Corners article.

Labels:

Renewable energy

Tuesday, July 8, 2014

The Rag Stealer gets a Playmate

Well not quite a playmate yet, she (the older dog - Xena) is still at the growling if-you-come-near-me stage. We have high hopes though. The new dog is SO much like Xena was when she was a pup - naughty.

The Vogue is going strong - still waiting for the front end work but in no great hurry - other stuff has moved to higher priority (new kitchen floor, new puppy) so it's better to wait for couple of weeks.

The Vogue is going strong - still waiting for the front end work but in no great hurry - other stuff has moved to higher priority (new kitchen floor, new puppy) so it's better to wait for couple of weeks.

Labels:

rag stealer

Sunday, June 22, 2014

Spare Front Springs Cleaned and Painted

I took a little bit of time over the weekend (Laurel says a lot of time), to wire brush, clean and paint the spare set of front springs for the Vogue.

Wire brushing them wasn't much fun. Here they have been wire brushed already.

Next was a coat of rust converter.

I also cleaned, rust converted, primed and painted the un-bent spare front anti-sway bar.

Then a coat of etch primer and a top coat or two.

Now I know that no-one likes to leave comments but is this colour too "loud". I still have time to paint them black.

They are a bit darker then it looks here. The Flash lit them up.

It's the same paint I used on the rear brake drums.

I read on some 4x4 and street car forums that it's a complete waste of time painting coil springs - oh well - they'll look better for a little while.

Wire brushing them wasn't much fun. Here they have been wire brushed already.

Next was a coat of rust converter.

I also cleaned, rust converted, primed and painted the un-bent spare front anti-sway bar.

Then a coat of etch primer and a top coat or two.

Now I know that no-one likes to leave comments but is this colour too "loud". I still have time to paint them black.

They are a bit darker then it looks here. The Flash lit them up.

It's the same paint I used on the rear brake drums.

I read on some 4x4 and street car forums that it's a complete waste of time painting coil springs - oh well - they'll look better for a little while.

Labels:

restoration,

steering,

suspension

Thursday, June 19, 2014

Front End work Delayed

I went to drop the Vogue in at around 5PM and the mechanics place was crowded with dead cars. They had an unexpected influx of problem vehicles. I really didn't want to leave the Vogue there with guys squeezing past it doing other work so I was quite happy just to leave it to sometime next week when the place had cleared a little.

This will give me a chance to clean and paint the spare sway bar and springs this weekend (yes I found two spare Vogue springs under the house). That way I might be able to clean and paint the wishbones on a weeknight - minimizing the time that the Vogue is dry-docked. There is always the option of not bothering the clean up the wishbones at all but Laurel (better half) says I wouldn't be happy if I did that. She's probably right.

It would be really nice to have this front end - maybe one day I'll pull it out.....

(Not mine but off a similar Rootes vehicle!)

Picture from Bill Ashby's Sunbeam Alpine

This will give me a chance to clean and paint the spare sway bar and springs this weekend (yes I found two spare Vogue springs under the house). That way I might be able to clean and paint the wishbones on a weeknight - minimizing the time that the Vogue is dry-docked. There is always the option of not bothering the clean up the wishbones at all but Laurel (better half) says I wouldn't be happy if I did that. She's probably right.

It would be really nice to have this front end - maybe one day I'll pull it out.....

(Not mine but off a similar Rootes vehicle!)

Labels:

restoration,

steering,

suspension

I'm getting Back on the Bus tonight

No it's not a failure. The Vogue goes "over the road" tonight so that the front end can be partially dis-assembled on Friday. I'll take the Bus home tonight and bring the Super Snipe to work tomorrow so that I can pick up the parts that have been removed and spend some time on them on the weekend.

Meanwhile here is a picture of my array of SuperPro bushings.

(The bushings are missing from the lower shocker mounts packet as they are already installed in the shockers - see previous post):

Lower front shocker bush kit - SPF0718-80K

Control arm upper bush kit - SPF0730K

Control arm lower bush kit - SPF1059K

Sway bar to control arm kit - SPF1060-19K (19 is the sway bar diameter in mm)

(Control arm = wishbone)

Meanwhile here is a picture of my array of SuperPro bushings.

(The bushings are missing from the lower shocker mounts packet as they are already installed in the shockers - see previous post):

Lower front shocker bush kit - SPF0718-80K

Control arm upper bush kit - SPF0730K

Control arm lower bush kit - SPF1059K

Sway bar to control arm kit - SPF1060-19K (19 is the sway bar diameter in mm)

(Control arm = wishbone)

Labels:

restoration,

steering,

suspension

Monday, June 16, 2014

Converting HQ Holden Shock Absorbers to Humber/Hillman

Dampers - OK they're dampers - but most folk call them Shock Absorbers.

The Holden H series shockers fit the Hillmans, Sunbeams and Singers(Humber Vogue) of the early sixties I'm told; so I just bought a set of Ultima Shock Absorbers off an eBay seller. They look about right - a minor change is all that is needed. Remove the bottom bushing and metal attachment and replace with a suitable Hillman style bushing. I have already bought some SuperPro SPF0718-80K bushings.

Step 1

Cut around one side of the bushing where a lip has formed when the bushing was installed.

Step 2

Drill out some rubber to make removing it easier. Try not to hit the metal.

Step 2.5

Make a mess.

Step 3

Place the shocker on a flat board and apply pressure with foot while pulling on the metal attachment with a big pair of multi-grips/pliers. A bit of rotational force helps.

Sorry no picture for this one but here the Holden style bushing has been removed (plus the one from the first shocker I did).

Step 4

Apply some of the supplied lubricant to one end of the new bushing.

Ready vice...

Step 5

Squeeze the bushing in with a vice. The rag is just so I don't take too much paint off the shocker.

Once you reach the limit of what can be done with the vice a little heal-of-hand thump seats the bushing nicely.

All done.

The Holden H series shockers fit the Hillmans, Sunbeams and Singers(Humber Vogue) of the early sixties I'm told; so I just bought a set of Ultima Shock Absorbers off an eBay seller. They look about right - a minor change is all that is needed. Remove the bottom bushing and metal attachment and replace with a suitable Hillman style bushing. I have already bought some SuperPro SPF0718-80K bushings.

Step 1

Cut around one side of the bushing where a lip has formed when the bushing was installed.

Step 2

Drill out some rubber to make removing it easier. Try not to hit the metal.

Step 2.5

Make a mess.

Step 3

Place the shocker on a flat board and apply pressure with foot while pulling on the metal attachment with a big pair of multi-grips/pliers. A bit of rotational force helps.

Sorry no picture for this one but here the Holden style bushing has been removed (plus the one from the first shocker I did).

Step 4

Apply some of the supplied lubricant to one end of the new bushing.

Ready vice...

Step 5

Squeeze the bushing in with a vice. The rag is just so I don't take too much paint off the shocker.

Once you reach the limit of what can be done with the vice a little heal-of-hand thump seats the bushing nicely.

All done.

Labels:

restoration,

suspension

Wednesday, June 4, 2014

About time for some Front End work

The Vogue's 49 year old control arm upper and lower bushes are on their last legs so I'm currently collecting parts to replace all the front end bushes - and shock absorbers.

I haven't been very happy with the knocks and squeaks that the Vogue front end has been emitting for a while, so last week, having got a ball-park price from elsewhere and not been happy with it, I visited Knox Tyrepower (over the road from work) to ask for some advice. These are the folk I spoke of here that gave the Vogue it's Silicone tyres and who mentioned in no uncertain terms at the time (point 5 in this post) that the front end was "on the way out".

As soon as I indicated why I was there, Ross took me by the arm and led me next door to the mechanics (unrelated business). They all appeared to know about the "Electric Vogue" and were keen to help out. They had a good look under the car (up on a hoist) and confirmed we needed the upper and lower wishbone (control arm) bushes renewed. This is a job I do not want to do as by the time I get someone else to press the old bushes out etc. it will become a major pain - I know I'll want to re-paint the whole front end! Spring compressors scare me too.

So this may look a bit different in a week or two.

(Knox Tyrepower has put tyres on, and aligned, all the cars in our family for a past 12 years and I have never been disappointed in their advice or workmanship - no they're not family!)

I haven't been very happy with the knocks and squeaks that the Vogue front end has been emitting for a while, so last week, having got a ball-park price from elsewhere and not been happy with it, I visited Knox Tyrepower (over the road from work) to ask for some advice. These are the folk I spoke of here that gave the Vogue it's Silicone tyres and who mentioned in no uncertain terms at the time (point 5 in this post) that the front end was "on the way out".

As soon as I indicated why I was there, Ross took me by the arm and led me next door to the mechanics (unrelated business). They all appeared to know about the "Electric Vogue" and were keen to help out. They had a good look under the car (up on a hoist) and confirmed we needed the upper and lower wishbone (control arm) bushes renewed. This is a job I do not want to do as by the time I get someone else to press the old bushes out etc. it will become a major pain - I know I'll want to re-paint the whole front end! Spring compressors scare me too.

So this may look a bit different in a week or two.

(Knox Tyrepower has put tyres on, and aligned, all the cars in our family for a past 12 years and I have never been disappointed in their advice or workmanship - no they're not family!)

Labels:

restoration,

steering,

suspension

Monday, May 19, 2014

A Quick De-rust and Small Respray

Over the past couple of years, the Vogue has been developing a small crease of rust where two body seams meet along the front behind the bumper bar. I have been trying to match the paint for the car but the original colour codes are unreadable due to paint drips. I have also had it for over 4 years now.

All in time to drive it to work today.

So given that the rust was becoming visible I set aside some time over the weekend to burr it out using my dremel and a miniature wire wheel, rust convert it (I actually did that stuff during the week at night), prime it, seam seal it, prime it again, then two base coats and two clear coats.

Where did I get the paint? I used supercheap auto's colour cards to get the closest match among 72,000 colours and they mixed me up an aerosol can.

I masked up 5-10mm either side of the seam as I didn't want to spray the whole lower front and the result is good - not perfect but good. You have to be looking for it.

The Vogue, missing bumper and grill, ready for clear coat. I hate overspray.

All in time to drive it to work today.

Labels:

respray,

restoration

Monday, May 5, 2014

Driver's seat fixed

One Sunday I finally got around to changing out the second faulty seat diaphragm - this time for webbing. I was amazed to see from this blog that it has been over 2 months since it tore. The seat base has had some of my trusty battery pack packaging foam supporting it.

First I removed the torn diaphragm. I also removed the two aluminium pieces at the sides so I could add more holes.

I had to temporarily un-thread the left hand front-to-back so allow me to get enough grip to stretch the side-to-side ones.

All done. The three middle side-to-side hooks are 30mm and are from the first seat diaphragm I bought - there is no reason I used them other than convenience. The Vogue originals and the ones I made were 20mm - you can see the difference.

The strange interleaving is because to front and rearmost straps would have been damaged by the webbing clamps if I had run the side-to-side trap across the bottom.

If this was being done while the seat was completely disassembled then you also would not need the aluminium pieces - just drill extra holes in the actual seat frame. Another time saver over what I did originally. The 0.8 stretch was about right for the base - I wouldn't change it.

I will post how it holds up over time but I really don't expect any problems at all as two or three straps can hold my 80kg weight easily - and there are eight.

The torn diaphragm. The steel inserts have torn out in four places at the rear of the seat (circled).

First I removed the torn diaphragm. I also removed the two aluminium pieces at the sides so I could add more holes.

I decided I would need five straps running side to side to support the foam so, fortunately, it only required three more to be drilled.

It was a bit cold in the garage so Laurel agreed that the workmate and vice could be brushed down and set up in the lounge room - together with a folding table.

First strap on. I used 0.86 stretch on the seat backs so we went with 0.8 on the base.

That is - measure the hole to hole dimension then subtract the size of the hooks and multiply the result by 0.8. Cut the webbing to that dimension.

Three front-to-back straps done.

I had to temporarily un-thread the left hand front-to-back so allow me to get enough grip to stretch the side-to-side ones.

All done. The three middle side-to-side hooks are 30mm and are from the first seat diaphragm I bought - there is no reason I used them other than convenience. The Vogue originals and the ones I made were 20mm - you can see the difference.

The strange interleaving is because to front and rearmost straps would have been damaged by the webbing clamps if I had run the side-to-side trap across the bottom.

It was a very comfy ride to work Monday and Tuesday.

Cost of the Premium Webbing plus clamps for the base was $26 - with postage from (www.diyupholsterysupplies.com.au/home/) This includes enough for the passenger seat when it inevitably fails. The webbing is also heaps easier to put on and really easy to "get it right". My advise - don't bother with the diaphragm approach at all.

Cost of the Premium Webbing plus clamps for the base was $26 - with postage from (www.diyupholsterysupplies.com.au/home/) This includes enough for the passenger seat when it inevitably fails. The webbing is also heaps easier to put on and really easy to "get it right". My advise - don't bother with the diaphragm approach at all.

If this was being done while the seat was completely disassembled then you also would not need the aluminium pieces - just drill extra holes in the actual seat frame. Another time saver over what I did originally. The 0.8 stretch was about right for the base - I wouldn't change it.

I will post how it holds up over time but I really don't expect any problems at all as two or three straps can hold my 80kg weight easily - and there are eight.

Labels:

seats

Subscribe to:

Posts (Atom)